Multi-material fluidic actuators

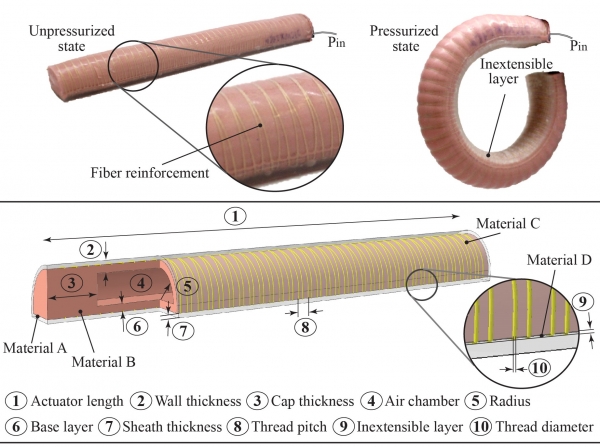

Soft fluidic actuators consisting of elastomeric matrices with embedded flexible materials (e.g. cloth, paper, fiber, particles) are of particular interest to the robotics community because they are lightweight, affordable and easily customized to a given application. These actuators can be rapidly fabricated in a multi-step molding process and can achieve combinations of contraction, extension, bending and twisting with simple control inputs such as pressurized fluid. In our approach is to use new design concepts, fabrication approaches and soft materials to improve the performance of these actuators compared to existing designs. In particular, we use motivating applications (e.g. heart assist devices, soft robotic gloves) to define motion and force profile requirements. We can then embed mechanical intelligence into these soft actuators to achieve these performance requirements with simple control inputs.

Soft fluidic actuators consisting of elastomeric matrices with embedded flexible materials (e.g. cloth, paper, fiber, particles) are of particular interest to the robotics community because they are lightweight, affordable and easily customized to a given application. These actuators can be rapidly fabricated in a multi-step molding process and can achieve combinations of contraction, extension, bending and twisting with simple control inputs such as pressurized fluid. In our approach is to use new design concepts, fabrication approaches and soft materials to improve the performance of these actuators compared to existing designs. In particular, we use motivating applications (e.g. heart assist devices, soft robotic gloves) to define motion and force profile requirements. We can then embed mechanical intelligence into these soft actuators to achieve these performance requirements with simple control inputs.

Modeling of soft actuators

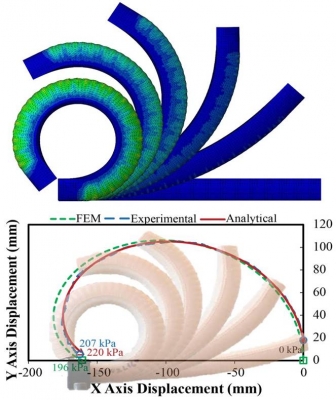

Characterizing and predicting the behavior of soft multi-material actuators is challenging due to the nonlinear nature of both the hyper-elastic material and the large bending motions they produce. We are working to comprehensively describe the principle of operation of these actuators through analytical, numerical and experimental approaches and characterize their outputs (motion and force) as a function of input pressure as well as geometrical and material parameters. Both models and experiments offer insight into the actuator behavior and the design parameters that affect it. We envision this work will lead to improved predictive models that will enable us to rapidly converge on new and innovative applications of these soft actuators.

Characterizing and predicting the behavior of soft multi-material actuators is challenging due to the nonlinear nature of both the hyper-elastic material and the large bending motions they produce. We are working to comprehensively describe the principle of operation of these actuators through analytical, numerical and experimental approaches and characterize their outputs (motion and force) as a function of input pressure as well as geometrical and material parameters. Both models and experiments offer insight into the actuator behavior and the design parameters that affect it. We envision this work will lead to improved predictive models that will enable us to rapidly converge on new and innovative applications of these soft actuators.

Sensing and control

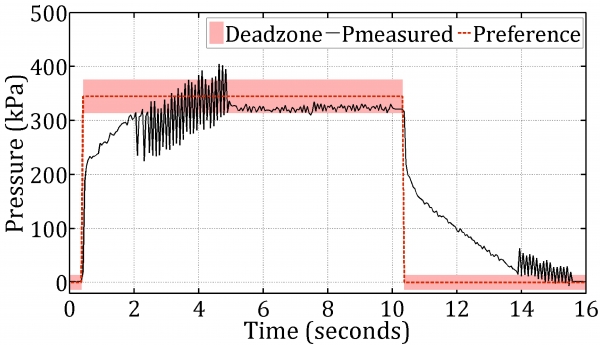

In order to control soft actuators, we need means of monitoring their kinematics, interaction forces with objects in the environment and internal pressure. We accomplish this through the use of fully soft sensors, developed with collaborators, and miniature or flexible sensors that can be incorporated into the actuator design during the manufacturing process. For power and control, we use off the shelf components such as electronic valves, pumps, regulators, sensors, and control boards etc. to rapidly modulate the pressure inside the chambers of the actuators using feedback control of pressure, motion and force. In addition, we can use the analytical models we develop to estimate state variables that may be difficult to measure directly.

In order to control soft actuators, we need means of monitoring their kinematics, interaction forces with objects in the environment and internal pressure. We accomplish this through the use of fully soft sensors, developed with collaborators, and miniature or flexible sensors that can be incorporated into the actuator design during the manufacturing process. For power and control, we use off the shelf components such as electronic valves, pumps, regulators, sensors, and control boards etc. to rapidly modulate the pressure inside the chambers of the actuators using feedback control of pressure, motion and force. In addition, we can use the analytical models we develop to estimate state variables that may be difficult to measure directly.

Translational applications

There are approximately four million chronic stroke survivors with hemiparesis in the US today and another six million in developed countries globally. In addition, there are millions of other individuals suffering from similar conditions. For the majority of these cases, loss of hand motor ability is observed, and whether partial or total, this can greatly inhibit activities of daily living (ADL) and can considerably reduce one’s quality of life. To address these challenges, we are developing a modular, safe, portable, consumable, at-home hand rehabilitation and assistive device that aims to improve patient outcomes by significantly increasing the quantity (i.e. time) and quality of therapy at a reduced cost while also improving independence of users with chronic hand disabilities by enabling them to perform activities of daily living.

There are approximately four million chronic stroke survivors with hemiparesis in the US today and another six million in developed countries globally. In addition, there are millions of other individuals suffering from similar conditions. For the majority of these cases, loss of hand motor ability is observed, and whether partial or total, this can greatly inhibit activities of daily living (ADL) and can considerably reduce one’s quality of life. To address these challenges, we are developing a modular, safe, portable, consumable, at-home hand rehabilitation and assistive device that aims to improve patient outcomes by significantly increasing the quantity (i.e. time) and quality of therapy at a reduced cost while also improving independence of users with chronic hand disabilities by enabling them to perform activities of daily living.

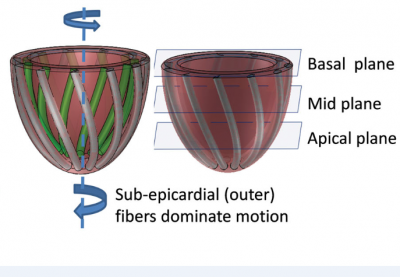

In the United States, the lifetime risk of developing heart failure is roughly 20%. The current clinical standard treatment is implantation of a ventricular assist device that contacts the patient’s blood and is associated with thromboembolic events, hemolysis, immune reactions and infections. We are applying the field of soft robotics to develop a benchtop cardiac simulator and a Direct Cardiac Compression (DCC) device employing soft actuators in an elastomeric matrix. DCC is a non-blood contacting method of cardiac assistance for treating heart failure involving implantation of a device that surrounds the heart and contracts in phase with the native heartbeat to provide direct mechanical assistance during the ejection phase (systole) and the relaxation phase (diastole) of the cardiac cycle.

In the United States, the lifetime risk of developing heart failure is roughly 20%. The current clinical standard treatment is implantation of a ventricular assist device that contacts the patient’s blood and is associated with thromboembolic events, hemolysis, immune reactions and infections. We are applying the field of soft robotics to develop a benchtop cardiac simulator and a Direct Cardiac Compression (DCC) device employing soft actuators in an elastomeric matrix. DCC is a non-blood contacting method of cardiac assistance for treating heart failure involving implantation of a device that surrounds the heart and contracts in phase with the native heartbeat to provide direct mechanical assistance during the ejection phase (systole) and the relaxation phase (diastole) of the cardiac cycle.